In 1946 George Morris & Son Limited acquired the old-established leather dressing business of Odell & Son, of Higham Ferrers. Owing to war-time restrictions and controls they could do no more than continue the business of dressing semi-chrome clothing and gloving leathers from the only raw material then at their disposal—rough tanned sheep skins. They did, however, decide upon a long-term policy of chrome tanning as soon as restrictions were lifted.

|

|

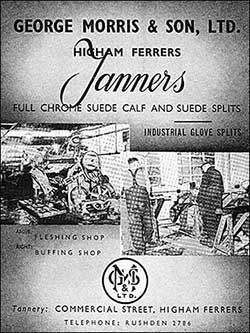

Advert 1950s

|

With the full co-operation of Cyril Norris & Son Ltd., Engineers, Higham Ferrers, they were able to institute the first phase of their new policy in 1951. This is now completed and, although small, the plan and layout is very modern and efficient, producing high-grade chrome suede calf and suede splits, two products requiring highly skilled labour, all of which has been trained by George Morris & Son Limited. Further plans for expansion will be put into effect as soon as a suitable site can be found, and these plans are calculated to widen considerably the range of products associated with their name.

So much for leather. Now let us turn to some of the marvellous machinery wrhich has been devised to perfect it and turn it into boots and shoes and slippers. Here are a fewr fascinating potted histories of firms whose business it is to build these machines (constantly improving on existing models to meet modern needs), increase production, improve efficiency and reduce manufacturing costs, so that wholesale and retail prices may be brought lower and lower.

For the beginnings of Cyril Norris & Son Ltd., of Higham Ferrers, we have to go back to approximately the year 1870 when the founder, Mr. W. Stafford, started up as a General Engineer. He was an engineer of the "old school," which meant an all-round engineer, including steam, water and agricultural engineering. He must have been the first person to make the leather drum that was used in the industry in this district, and he acquired a name for work of sound engineering quality.

From the old days of Mr. W. Stafford, when drums were just receptacles for retaining the liquor and leather, and rotating same, the manufacture in drums has advanced to such an extent that in certain instances they have to run for forty-eight hours without stopping, and their cost with their special equipment, etc. is now up to £2,000 each. When the business was taken over by Mr. Cyril Norris in 1928, only two men were employed—the firm's present employees number approximately ninety.

|